2025 Top Uses for Galvanized Iron Drum in Industrial Applications

In the fast-evolving landscape of industrial applications, the versatility of the galvanized iron drum has increasingly become a focal point for efficiency and sustainability. Renowned expert in industrial materials, Dr. James Reynolds, emphasizes this trend by stating, "The galvanized iron drum is not just a container; it is a crucial component of modern industrial processes." This sentiment reflects the dual role of these drums as both storage solutions and integral parts of manufacturing workflows.

From chemical processing to waste management, the applications for galvanized iron drums are wide-ranging and vital. With their corrosion-resistant properties, these drums provide an optimal solution for storing various substances, ensuring safety and longevity. As industries look towards environmentally friendly practices, the galvanized iron drum emerges as a sustainable choice that supports recycling initiatives and reduces material waste.

As we explore the top uses for galvanized iron drums in 2025, it becomes essential to understand their evolving significance within industrial sectors. The ability to adapt and innovate will determine how effectively these drums will meet future demands. Consequently, their role is not only significant in the current landscape but also critical as we advance towards more sustainable industrial practices.

Overview of Galvanized Iron Drums in Industry

Galvanized iron drums have become a staple in various industrial applications due to their exceptional durability and resistance to corrosion. Coated with a layer of zinc, these drums can withstand harsh environmental conditions, making them suitable for storage and transportation of a wide range of materials, including chemicals, oils, and food products. According to a report by MarketsandMarkets, the industrial container market is projected to reach $150 billion by 2025, with galvanized iron drums playing a crucial role due to their cost-effective nature and versatility.

The versatility of galvanized iron drums is highlighted by their application in sectors such as manufacturing, pharmaceuticals, and waste management. For instance, the pharmaceutical industry often requires stringent safety measures for material storage, and galvanized iron drums provide the necessary compliance with regulations while ensuring the integrity of the contents. Furthermore, the United Nations Environment Programme emphasizes the importance of using robust containers for hazardous waste disposal, where galvanized drums are favored for their ability to prevent leaks and maintain safety standards.

In addition to their practical applications, the use of galvanized iron drums contributes to sustainability efforts within industries. Their longevity means fewer replacements are necessary, reducing waste and resource consumption. A recent study by the National Institute of Standards and Technology indicated that using durable materials like galvanized iron could decrease overall material waste by up to 30%, aligning with the global push towards more sustainable industrial practices. As industries continue to seek reliable and eco-friendly storage solutions, the significance of galvanized iron drums is anticipated to grow even further by 2025.

Advantages of Using Galvanized Iron Drums

Galvanized iron drums have gained popularity in various industrial applications due to their numerous advantages. One of the main benefits of using galvanized iron is its exceptional corrosion resistance. The zinc coating applied to the iron surface forms a protective barrier that safeguards the drum from moisture and corrosive substances, thereby extending the lifespan of the container. This durability makes galvanized iron drums ideal for storing and transporting chemicals, liquids, and other materials that could potentially cause damage to unprotected containers.

In addition to their corrosion resistance, galvanized iron drums are also known for their structural strength and reliability. Their robust design can withstand harsh environmental conditions, making them suitable for outdoor use as well as in challenging industrial settings. Furthermore, these drums are lightweight compared to their steel counterparts, facilitating easier handling and transportation. The combination of resilience and ease of use allows businesses to streamline their operations while minimizing the risk of product spoilage or damage, reinforcing the value of using galvanized iron drums in industrial processes.

2025 Top Uses for Galvanized Iron Drum in Industrial Applications - Advantages of Using Galvanized Iron Drums

| Use Case |

Advantages |

Common Industries |

Estimated Market Growth (%) |

| Storage of Hazardous Chemicals |

Corrosion resistance, durability |

Chemical Manufacturing, Pharmaceuticals |

5% |

| Water Storage |

Long lifespan, safe for drinking water |

Construction, Agriculture |

3% |

| Transporting Liquids |

Leak-proof, robust structure |

Logistics, Oil and Gas |

4% |

| Waste Disposal |

Resistant to rust and decay |

Environmental Services, Recycling |

6% |

| Rainwater Harvesting |

Durable and easy to install |

Construction, Landscaping |

7% |

Common Industrial Applications of Galvanized Iron Drums

Galvanized iron drums are increasingly becoming a staple in various industrial applications due to their durability and resistance to corrosion. According to a recent market analysis published by Research and Markets, the demand for galvanized iron products is projected to grow at a CAGR of 5.6% from 2021 to 2026. This growth is driven by their extensive use in sectors such as chemicals and petroleum, where the storage of hazardous materials requires dependable and long-lasting containers.

One of the principal applications of galvanized iron drums is in the transportation and storage of bulk liquids. Their robust construction ensures that they can withstand harsh environmental conditions and prevent leakage. The chemical industry, which accounted for approximately 37% of the total consumption of industrial drums in 2022, heavily relies on these drums for safe handling of solvents, acids, and other corrosive substances. Additionally, the food processing sector utilizes galvanized iron drums for storing non-perishable items, benefiting from the FDA-approved coatings that maintain product integrity and safety.

Another significant industrial application is the use of galvanized iron drums in construction and waste management. These drums are often employed to collect and dispose of construction debris, contributing to sustainable practices in waste management. The Environmental Protection Agency (EPA) reports that proper disposal methods can reduce construction waste by up to 70%, highlighting the importance of reliable containers like galvanized iron drums in achieving environmental goals. Their versatility and reliability make them indispensable in various industrial settings, underscoring their role in enhancing operational efficiencies.

2025 Top Uses for Galvanized Iron Drum in Industrial Applications

Best Practices for Storing and Handling Galvanized Iron Drums

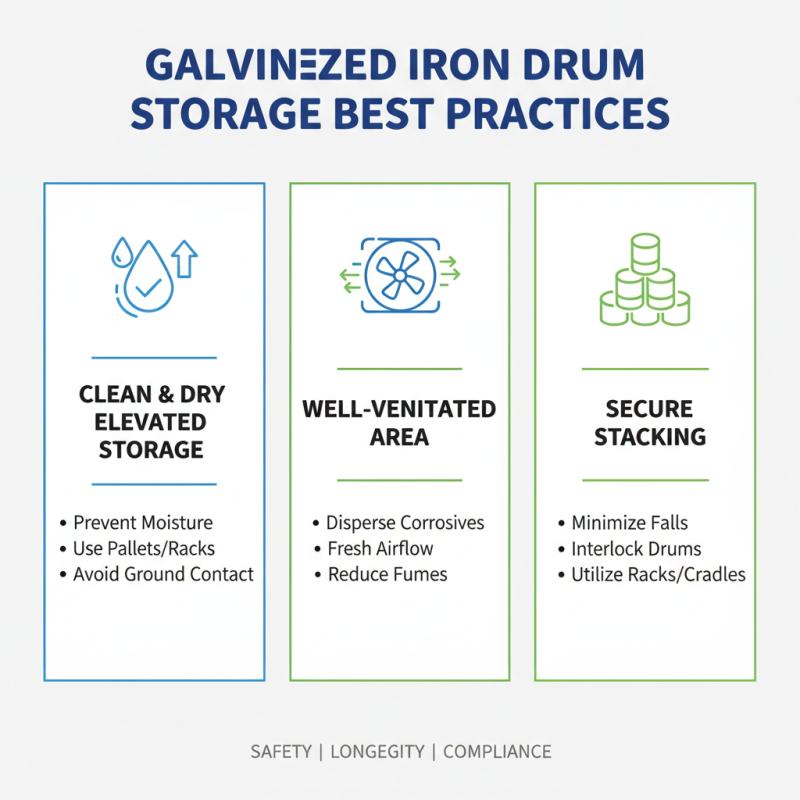

When it comes to storing and handling galvanized iron drums, adhering to best practices is essential for ensuring safety and longevity. Proper storage begins with a clean, dry area that is preferably elevated to prevent moisture accumulation. It is crucial to ensure that the storage location is well-ventilated to avoid the buildup of corrosive substances that may compromise the integrity of the drums. Additionally, drums should be stacked in a way that minimizes the risk of falls or toppling, using pallets or racks designed specifically for such storage.

Handling galvanized iron drums requires careful consideration to avoid damage to the drums and injury to workers. When moving the drums, it is advisable to use appropriate lifting equipment or machinery to manage their weight safely. Workers should be trained in proper techniques to minimize strain and maximize efficiency. Additionally, any loading and unloading procedures should be executed on stable surfaces to further reduce hazards. Regular inspections of both the drums and the handling equipment can prevent accidents, ensuring that the galvanized iron drums remain in optimal condition throughout their storage and usage periods.

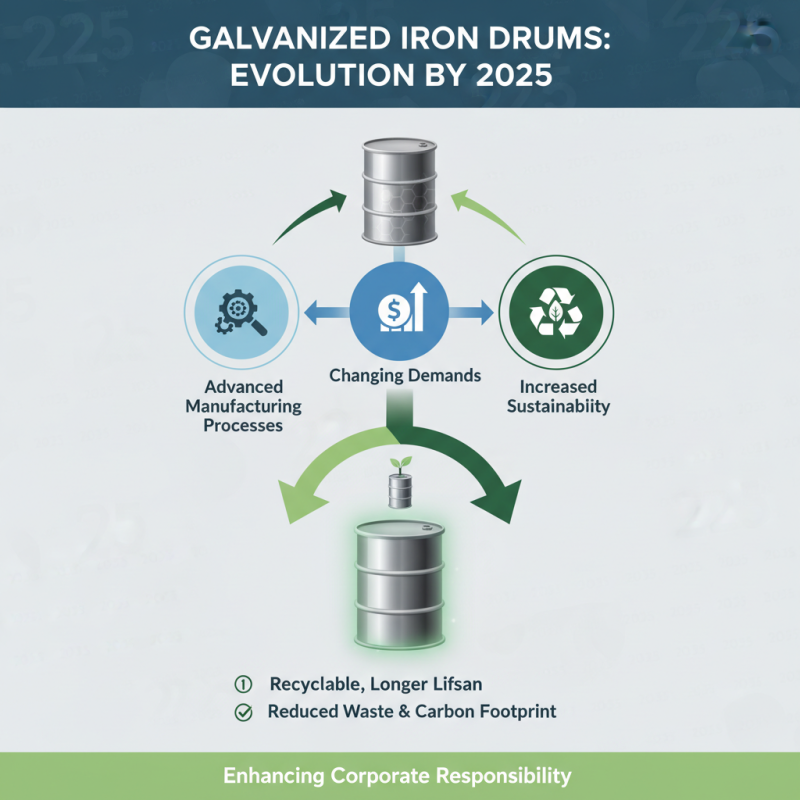

Future Trends in the Use of Galvanized Iron Drums in Industry

The use of galvanized iron drums in industrial applications is expected to evolve significantly by 2025, driven by advancements in manufacturing processes and changing market demands. One prominent trend is the increased emphasis on sustainability. Industries are increasingly focusing on environmentally friendly practices, leading to a rise in the use of galvanized iron drums that are recyclable and have a longer lifespan than traditional materials. This shift not only reduces waste but also enhances corporate responsibility, as companies seek to reduce their carbon footprints.

Another notable trend is the integration of smart technology into galvanized iron drums. As the Internet of Things (IoT) continues to expand, industrial drums may soon be equipped with sensors and tracking systems to monitor contents, conditions, and location in real time. This technological advancement can improve inventory management and enhance safety by providing crucial data regarding the treatment of hazardous materials. Furthermore, industries may adopt customizable designs that allow for better adaptability to diverse operational needs, indicating a versatile future for galvanized iron drums in various sectors.