Ultimate Tips for Using Galvanized Iron Drum in Your Projects

When embarking on creative projects, the choice of materials can significantly influence both the aesthetics and functionality of the end product. One versatile option that has gained popularity in various applications is the galvanized iron drum. Its robust construction, coupled with resistance to corrosion, makes it an ideal choice for builders, artists, and DIY enthusiasts alike. In this article, we will explore ultimate tips for effectively utilizing galvanized iron drums in your projects, highlighting their diverse uses and the benefits they confer.

From crafting unique garden planters to constructing functional storage solutions, the potential applications of galvanized iron drums are vast. Their durability ensures that they can withstand outdoor exposure, while their industrial appeal adds a modern touch to any setting. As we delve into the various ways you can incorporate galvanized iron drums into your work, we aim to inspire innovation and creativity. Whether you’re looking to enhance your home décor or seeking practical solutions for organization, galvanized iron drums offer a wealth of possibilities that are both practical and visually appealing.

Understanding Galvanized Iron Drums: Properties and Benefits

Galvanized iron drums are widely recognized for their durability and resistance to corrosion, making them an excellent choice for a variety of projects. The galvanization process involves coating iron with a layer of zinc, which not only enhances strength but also protects against rust and deterioration when exposed to the elements. This property makes galvanized iron drums ideal for outdoor use, such as storage for liquids or materials susceptible to weather-related wear and tear. Their robust construction also ensures they can withstand rough handling, making them suitable for industrial applications.

When utilizing galvanized iron drums in your projects, consider the following tips: first, ensure proper cleaning and preparation before any modifications. This step is crucial if you're planning to paint or modify the drum for specific uses. Second, take advantage of the drums' versatility by repurposing them; for instance, they can be converted into effective storage solutions or transformed into unique planters for your garden. Lastly, always check for any pre-existing damage before use, as this can affect the drum's performance. By understanding the properties and benefits of galvanized iron drums, you can maximize their potential in your projects.

Ultimate Tips for Using Galvanized Iron Drum in Your Projects

| Property |

Description |

Benefits |

| Corrosion Resistance |

Galvanized iron is coated with zinc to prevent rust. |

Increased lifespan and durability in harsh environments. |

| Weight |

Galvanized iron drums are relatively lightweight. |

Easier transportation and handling compared to heavier materials. |

| Versatility |

Can be used for storage, waste disposal, and industrial applications. |

Suitable for various projects and purposes. |

| Cost-Effectiveness |

Relatively inexpensive compared to stainless steel alternatives. |

Budget-friendly option for many projects. |

| Safety |

Manufactured under strict safety standards. |

Safe for handling and storage of various materials. |

Common Uses of Galvanized Iron Drums in Various Projects

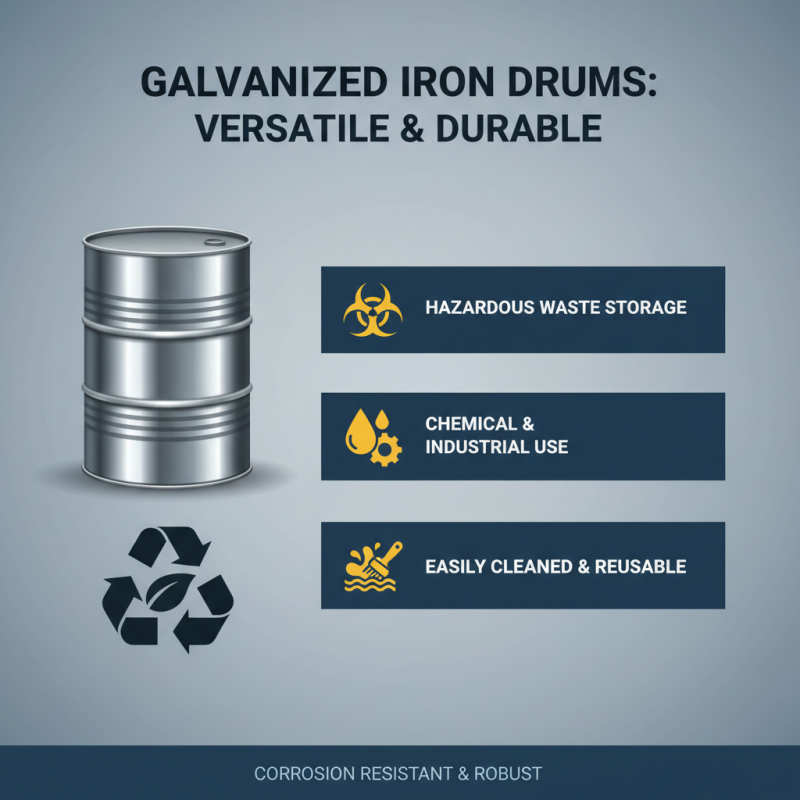

Galvanized iron drums are highly versatile and commonly used in a variety of projects due to their durability and corrosion resistance. One of the most prevalent uses is in waste management. These drums are ideal for securely storing and transporting hazardous materials, chemicals, and other waste products. Their robust construction ensures that they can withstand harsh environments while maintaining the integrity of their contents. Furthermore, galvanized iron drums can be easily cleaned and reused, making them an environmentally friendly option for waste disposal.

In addition to their role in waste management, galvanized iron drums are often employed in agricultural applications. Farmers use them for storing feed, water, and other essential supplies. The drums can be sealed to prevent contamination, and their sturdy nature protects the contents from weather elements and pests. Additionally, these drums serve as effective rainwater collectors, providing an eco-friendly solution for irrigation and other watering needs. The versatility of galvanized iron drums makes them a staple in both industrial and agricultural settings, showcasing their practicality in a wide range of projects.

Step-by-Step Guide to Preparing Galvanized Iron Drums for Use

When preparing galvanized iron drums for your projects, the first crucial step is to thoroughly clean the drum. Begin by removing any residues or contaminants from previous uses. Use a mild detergent and a scrubbing brush to scrub the interior and exterior surfaces. Rinse the drum thoroughly with water and allow it to dry completely. This not only ensures a clean working surface but also prevents any undesirable chemical reactions with materials you might store or use within the drum.

Next, inspect the drum for any signs of rust or corrosion. Although galvanized iron provides some level of rust resistance, it is essential to check for any damages that could affect the drum's longevity. If you find any rust spots, sand them down gently to reveal clean metal and apply a rust inhibiting primer or paint to protect the area. It’s also a good idea to seal any openings or seams with appropriate sealants, ensuring a secure and effective container for your project. By taking these preparatory steps, you will significantly enhance the usability and durability of galvanized iron drums in your various applications.

Best Practices for Maintenance and Care of Galvanized Iron Drums

When working with galvanized iron drums, proper maintenance and care are essential to ensure their longevity and functionality. Regular inspection is a key practice that helps identify any signs of deterioration, such as rust or corrosion, which can compromise the drum's integrity. It's advisable to clean the drums periodically using a mild detergent and water to remove dirt and grime. This not only keeps the drums looking good but also helps prevent any buildup that could lead to rust formation. Additionally, storing the drums in a dry, shaded area can significantly reduce the risk of moisture-related damage.

Another important aspect of maintenance is the careful handling of the drums during transport and usage. Avoiding abrasive surfaces and preventing heavy impacts can preserve the protective galvanized coating. In cases where the coating has been scratched or damaged, applying a zinc-rich paint or a protective sealant can help restore its durability. Furthermore, maintaining proper ventilation is crucial when storing the drums, as it reduces moisture accumulation inside and minimizes the risk of corrosion. By adhering to these best practices, you can effectively prolong the life of your galvanized iron drums and keep them functioning optimally for various projects.

Maintenance and Care of Galvanized Iron Drums

Safety Considerations When Working with Galvanized Iron Drums

When working with galvanized iron drums, safety should always be a top priority. These drums are commonly used in various industries for storage and transportation, but improper handling can lead to severe injuries. According to a report by the National Institute for Occupational Safety and Health (NIOSH), over 40% of workplace injuries related to material handling involve either lifting or transporting containers like metal drums. Ensuring that employees are trained in proper lifting techniques and utilizing appropriate personal protective equipment (PPE) can significantly mitigate these risks.

Additionally, it's crucial to address the potential hazards associated with galvanized iron drums during both storage and transport. The American National Standards Institute (ANSI) emphasizes the importance of labeling and maintaining clear communication regarding the contents of any drum. Drums should always be stored upright, on level ground, and away from flammable materials to prevent accidents. Moreover, workers should inspect the drums for leaks or corrosion regularly; the Centers for Disease Control and Prevention (CDC) notes that exposure to rust and exposure to zinc fumes created during welding or cutting can lead to serious respiratory issues. Implementing strict safety protocols not only protects workers but also ensures compliance with industry regulations.