Top Reasons to Buy an Iron Drum for Sale in 2025

The demand for storage solutions that ensure safety and efficiency continues to rise, with projections indicating a significant increase in the market for industrial containers. According to a report by ResearchAndMarkets, the global industrial drums market is expected to reach USD 17.5 billion by 2025, driven by the growing need for hazardous materials storage and the rise in production activities across various industries. Within this sector, the "iron drum for sale" segment is anticipated to play a crucial role due to its durability, cost-effectiveness, and environmental compliance.

Iron drums are recognized for their exceptional strength and resistance to impact, making them ideal for transporting and storing liquids and solids, particularly in the chemical and oil industries. Moreover, the increasing focus on sustainability and recycling practices is further elevating the demand for metal drums, as they can be reused and recycled, minimizing waste. As industries evolve and seek reliable solutions that can meet stringent safety standards, investing in high-quality iron drums will be vital for organizations aiming to enhance their operational efficiency and adhere to regulatory requirements.

In light of these trends, understanding the top reasons to buy an iron drum for sale in 2025 is essential for businesses looking to optimize their storage solutions and maintain competitiveness in a rapidly changing market landscape.

Key Benefits of Using Iron Drums in Various Industries

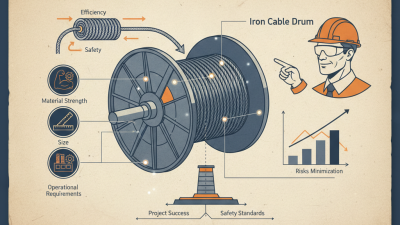

Iron drums are invaluable assets across multiple industries due to their durability, versatility, and capacity for secure storage and transportation of a variety of materials. One of the primary benefits of using iron drums is their resistance to corrosion and extreme environmental conditions, making them ideal for storing liquids and hazardous materials. Their strong construction ensures that they can withstand significant impact and rough handling, which is especially important in sectors like construction, manufacturing, and chemical processing.

Furthermore, iron drums offer excellent efficiency in logistics and inventory management. They are designed for easy stacking and can fit neatly into standard shipping containers, optimizing space during transport. This efficiency is complemented by their ability to be recycled and repurposed, contributing to sustainable practices within industries. Additionally, the availability of sizes and configurations tailored to specific applications makes iron drums an adaptable solution for diverse operational needs, ensuring that businesses can find the right fit for their storage and transportation requirements.

Durability and Longevity: Why Iron Drums Outperform Other Materials

When considering storage solutions for various materials, the choice of drum type can significantly impact durability and longevity. Iron drums have emerged as a preferred option due to their superior strength and resistance to environmental factors. According to a recent report by the National Institute of Standards and Technology, metal containers, particularly those made of iron, exhibit a lifespan that can exceed 30 years with proper maintenance, compared to plastic alternatives that often degrade within a decade. The robust structure of iron not only withstands heavy impacts but also offers enhanced protection against rust when treated with appropriate coatings, ensuring reliability in various storage conditions.

Additionally, iron drums excel in temperature resilience, managing extreme heat and cold far more effectively than plastic or composite materials. An analysis by the American Society for Testing and Materials highlights that iron drums maintain their integrity in temperature ranges from -40°F to 210°F, making them ideal for industries requiring secure storage solutions under varying climatic conditions. This durability translates into lower replacement costs over time, reinforcing the economic advantage of investing in iron drums over time-sensitive and less durable materials. In conclusion, the attributes of iron drums not only meet industry standards but also set a benchmark for longevity and resilience, making them a wise choice for businesses in 2025 and beyond.

Cost-Effectiveness: Analyzing the Long-Term Savings of Iron Drums

In 2025, the trend of investing in iron drums can be attributed to their cost-effectiveness, which is becoming increasingly relevant in various industries. According to a report by the Packaging Industry Association, the demand for durable and reusable packaging solutions is expected to grow by 15% over the next five years. Iron drums, known for their longevity and resilience, provide a robust answer to this need, boasting an average lifespan of over 20 years with proper maintenance. This durability significantly reduces the frequency of replacements compared to other materials such as plastic, resulting in lower long-term expenditures.

Furthermore, the cost savings associated with iron drums extend beyond their initial purchase price. Estimates from the Industrial Packaging Federation indicate that businesses leveraging iron drums can save upwards of 30% on waste management and disposal costs due to their recyclability and the ability to withstand harsher environmental conditions. Industries such as chemicals, oil, and food production report that iron drums, when purchased in bulk, can further enhance savings through reduced shipping and handling costs, as their sturdy construction minimizes damage during transport. By considering these factors, organizations are increasingly recognizing that investing in iron drums is not just a sustainable choice but also a strategic financial decision that drives down operational costs in the long run.

Cost-Effectiveness of Iron Drums: Long-Term Savings Analysis (2025)

Versatility of Iron Drums: Applications Across Different Sectors

Iron drums are becoming increasingly popular across various sectors due to their inherent versatility. According to a recent market analysis report by Allied Market Research, the global market for industrial drums is projected to reach over $10 billion by 2025, driven largely by the increasing demand in industries such as chemicals, food and beverage, and pharmaceuticals. Iron drums are preferred for their durability and ability to safely store hazardous materials, which makes them a critical component in many industrial supply chains.

In the chemical industry, iron drums are essential for transporting solvents, acids, and other corrosive substances. Their robust construction ensures that the contents remain secure during transit, minimizing the risk of spillage and contamination. In the food and beverage sector, iron drums are often used for storing bulk ingredients, having passed rigorous safety standards that protect food quality. The pharmaceutical industry also relies on iron drums for maintaining the integrity of sensitive products, as their airtight seals provide a necessary barrier against environmental factors.

Tips for selecting the right iron drum include assessing the specific requirements of your application, such as capacity, **lining**, and regulatory compliance. Always opt for drums that meet industry standards to ensure safety and reliability. Additionally, consider the reuse and recycling potential of the drums to contribute to sustainability efforts while reducing long-term costs.

Environmental Considerations: The Sustainability of Iron Drum Production

When considering the purchase of an iron drum in 2025, it's essential to weigh the environmental aspects of its production. Iron drums are increasingly recognized for their sustainability, stemming from the recyclable nature of iron itself. The production process can be designed to minimize waste and energy consumption, particularly when manufacturers employ advanced technologies and practices aimed at reducing their carbon footprint. This focus on sustainability not only benefits the environment but also enhances the appeal of iron drums as a responsible choice for consumers.

**Tips**: Before purchasing, look for suppliers that prioritize eco-friendly practices and sourcing methods. Understanding their production processes can help you select a product that aligns with your values.

Additionally, the lifecycle of an iron drum contributes to its sustainability. These drums can be reused and recycled, which means they can serve multiple purposes over time, reducing the demand for new resources. As awareness about environmental issues grows, choosing products that are designed with sustainability in mind becomes increasingly important. Iron drums, with their long-lasting durability and ability to be repurposed, stand out as an excellent option for those looking to make eco-conscious decisions.

**Tips**: Consider the end-of-life plan for your iron drum. Research how to recycle it properly or find creative ways to repurpose it in your home or business to maximize its utility and reduce waste.