| 1. Choose the Right Size |

Select a drum size that fits your storage needs. |

Optimal space utilization and better organization. |

| 2. Proper Sealing |

Ensure the lid is tightly sealed to prevent contamination. |

Maintains product integrity and safety. |

| 3. Label Clearly |

Use clear labels to identify contents. |

Eases handling and reduces mistakes. |

| 4. Regular Inspection |

Check drums for any signs of damage or rust. |

Ensures longevity and safety of storage. |

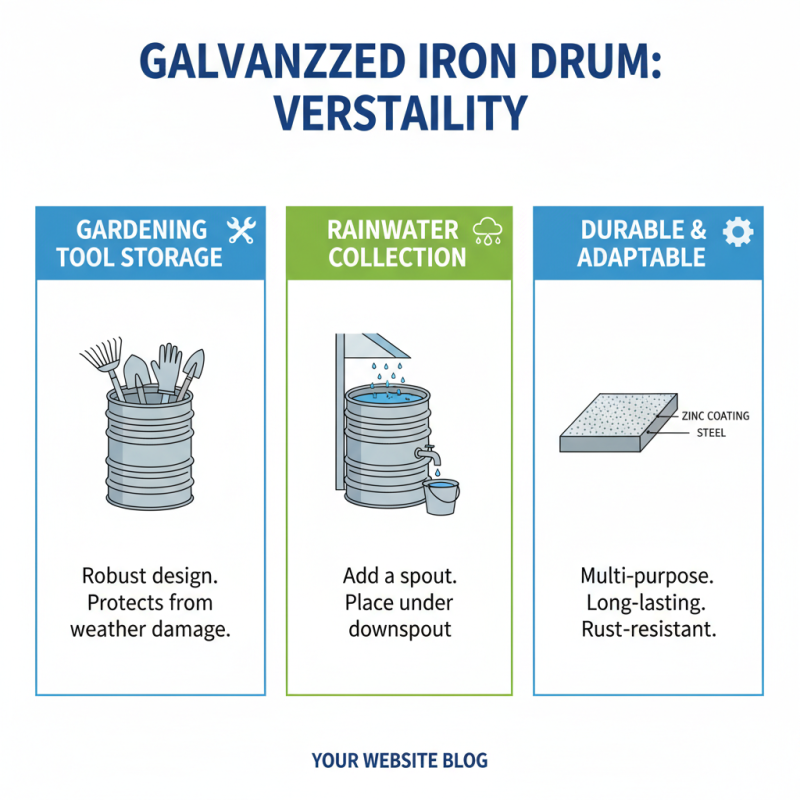

| 5. Use for Versatile Applications |

Utilize drums for storage, waste, or transport. |

Maximizes functionality and efficiency. |

| 6. Consider Temperature Effects |

Avoid extreme temperatures that could affect contents. |

Protects material from degradation. |

| 7. Ensure Proper Handling |

Use appropriate lifting techniques and tools. |

Reduces risk of injury and damage. |

| 8. Store Safely |

Keep drums on stable surfaces away from hazards. |

Enhances safety and reduces spills. |

| 9. Clean Before Reuse |

Thoroughly clean and disinfect before refilling. |

Prevents contamination of new contents. |

| 10. Dispose Responsibly |

Follow regulations for disposing of old drums. |

Contributes to environmental sustainability. |