How to Choose the Right Iron Cable Drum for Your Needs: A Comprehensive Guide

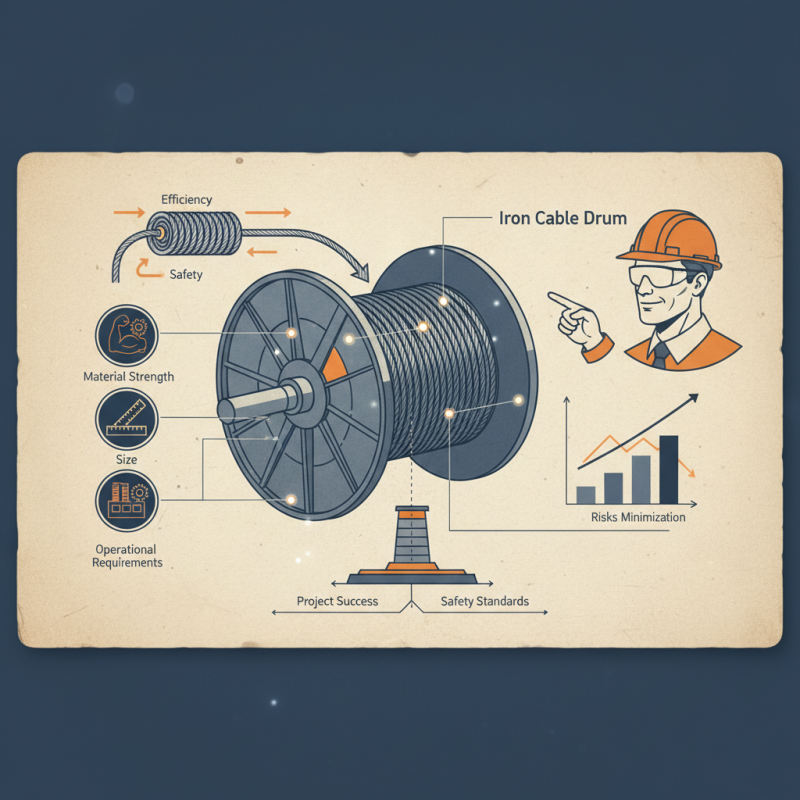

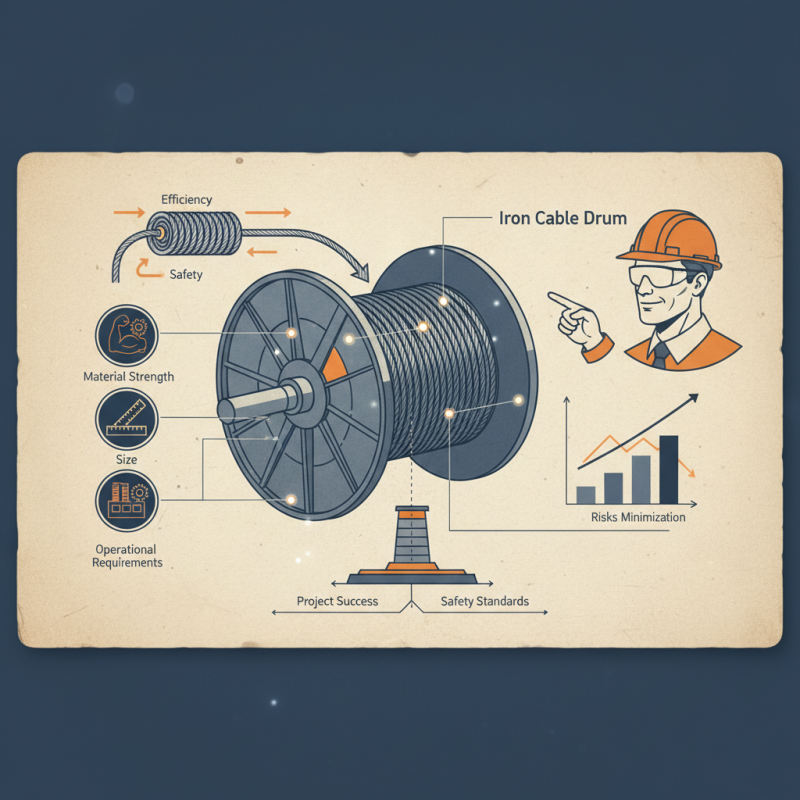

Choosing the right iron cable drum is crucial for ensuring efficiency and safety in various industrial applications. As expert in the field, Dr. John Harrison, an esteemed engineer with over 20 years of experience in cable management solutions, states, "The effectiveness of your cable management system hinges on selecting the optimal iron cable drum that suits your specific needs." This underscores the importance of understanding the various factors that influence the selection process.

In this comprehensive guide, we will delve into the critical aspects of iron cable drum selection, taking into account factors such as material strength, size, and operational requirements. The right iron cable drum not only enhances productivity but also minimizes risks associated with improper cable handling. As we explore the essential characteristics and specifications necessary for identifying the perfect drum for your application, you will gain valuable insights into making an informed decision that aligns with your operational goals. This knowledge can significantly impact overall project success and safety standards in the workplace.

Understanding the Purpose of Iron Cable Drums in Various Applications

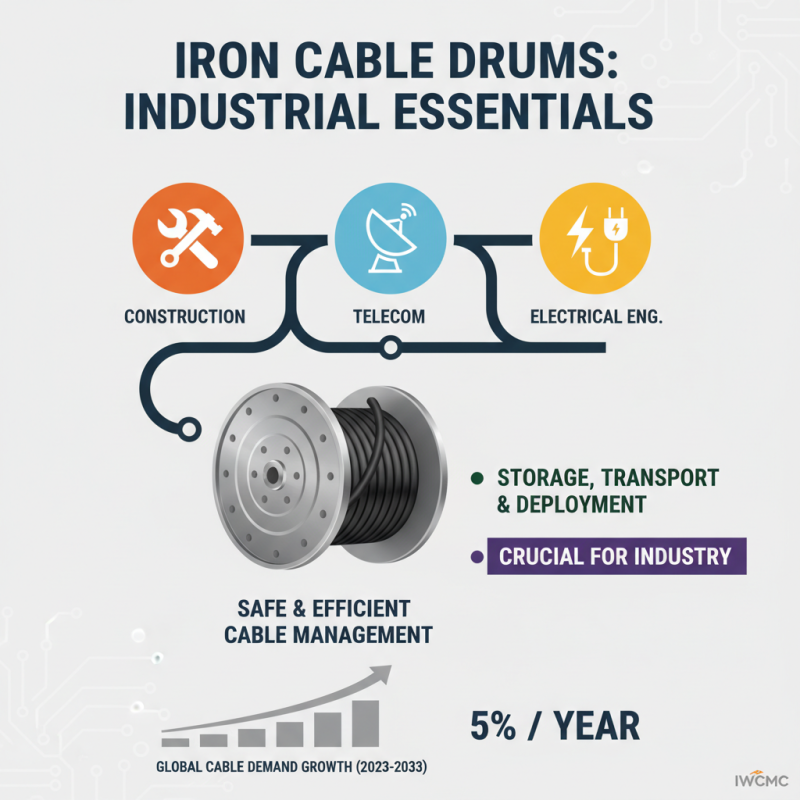

Iron cable drums play a crucial role in various industries by facilitating the safe and efficient storage, transport, and deployment of cables. These drums serve as essential components in sectors such as construction, telecommunications, and electrical engineering. According to a report by the International Wire and Cable Manufacturers Committee, the global demand for cables is expected to grow by approximately 5% per year over the next decade, underscoring the importance of quality cable management solutions like iron cable drums.

When selecting an iron cable drum, it is vital to understand the specific requirements of the application. For instance, heavy-duty drums are typically used in industrial environments where cables must endure harsh conditions, while lighter drums may suffice for residential or low-demand applications. A study from the National Electrical Manufacturers Association highlights that improper cable management can lead to significant economic losses, amounting to billions annually due to inefficiencies in installation and maintenance. Thus, choosing the right drum not only enhances operational efficiency but also contributes to overall project timelines and cost-effectiveness.

Furthermore, the design and construction of iron cable drums can impact their performance across applications. For example, a wider flange can prevent cable from slipping off during transport, whereas reinforced sides may be necessary for heavy-duty cables used in mining or offshore operations. Understanding these design nuances allows businesses to align their cable management needs with the right drum specifications, ultimately optimizing their operational capabilities.

Key Factors to Consider When Selecting an Iron Cable Drum

When selecting an iron cable drum, several key factors should be considered to ensure it meets your specific requirements. First, the drum's capacity is crucial. Assess the size and weight of the cables you intend to use, as this will determine the drum’s volume and load-bearing specifications. Choosing a drum that can accommodate your cables without overloading is essential to prevent damage and ensure safe handling.

Another important consideration is the material and construction of the iron cable drum. Different manufacturing processes can affect the drum's durability and resistance to environmental conditions. Opt for a drum that has a robust design capable of withstanding harsh weather or heavy-duty use, which can extend its lifespan and reliability in various applications. Additionally, consider the drum's portability features, such as lifting mechanisms or wheels, which can enhance efficiency during transportation and handling on-site.

These factors collectively will help ensure you choose the right iron cable drum tailored to your operational needs.

Different Types of Iron Cable Drums and Their Features

Iron cable drums come in various types, each designed to meet specific requirements based on their features and applications. One of the most common types is the standard drum, which is ideal for general use in industries that require cable storage and transport. These drums typically feature a robust construction that can withstand heavy loads, making them suitable for both indoor and outdoor environments. The standard design allows for easy stacking and secure transportation, ensuring that cables are kept organized and protected.

Another notable type of iron cable drum is the split drum, which is designed for cases where multiple types of cables need to be wound separately. This drum features a divider that allows distinct sections for different cables, preventing tangling and facilitating easy access during installation or maintenance. Additionally, some split drums come with adjustable flanges to accommodate varying cable sizes, enhancing their versatility in diverse applications.

Specialty drums, such as those equipped with braking systems or hydraulic capabilities, provide enhanced control during cable unrolling. This is particularly useful in applications where precise cable deployment is critical, such as in construction sites or film productions. Understanding the specific features and applications of these different types of iron cable drums can help you select the right one to ensure efficiency and safety in your operations.

Determining the Right Capacity and Size for Your Project

When selecting the right iron cable drum for your project, determining the appropriate capacity and size is crucial to ensure optimal performance and safety. Industry reports indicate that both the tension on the cable and the weight of the load are significant factors in this determination. For instance, a cable drum typically needs to support a load that correlates to the maximum tension of the cable, which can vary based on the material and diameter of the cables used. According to a study by the International Wire and Cable Symposium, the correct sizing of cable drums can enhance operational efficiency by up to 20%, reducing wear on cables and minimizing maintenance costs.

Moreover, understanding the total length and diameter of the wire to be wound is fundamental in establishing the right dimensions of the drum. Professionals suggest that for every 1,000 feet of cable, an additional 10% in drum size is advisable to accommodate for overlaps that occur during winding. Furthermore, the capacity of a cable drum can influence handling and transportation; a heavier drum can complicate maneuverability, which may not be ideal in tight workspaces. The Cable & Connectivity Association highlights that the average diameter of cable drums used in construction ranges from 24 to 72 inches, factoring in standard wire gauges and application requirements. Thus, careful evaluation of size and capacity is essential for maximizing the effectiveness of cable handling operations.

How to Choose the Right Iron Cable Drum for Your Needs: A Comprehensive Guide - Determining the Right Capacity and Size for Your Project

| Drum Type |

Capacity (kg) |

Diameter (cm) |

Width (cm) |

Material |

| Standard Iron Drum |

1200 |

80 |

60 |

Iron |

| Reinforced Iron Drum |

1500 |

90 |

70 |

Reinforced Iron |

| Heavy-Duty Iron Drum |

1800 |

100 |

80 |

Heavy Duty Iron |

| Lightweight Iron Drum |

800 |

70 |

50 |

Iron |

| Compact Iron Drum |

600 |

60 |

40 |

Iron |

Best Practices for Maintenance and Care of Iron Cable Drums

Proper maintenance and care of iron cable drums are essential to ensure their longevity and optimal performance. Regular inspections should be conducted to check for signs of wear, rust, or damage. It's important to keep the drums clean and free of debris, as dirt can lead to corrosion and impair their functionality. When not in use, store the drums in a dry environment to avoid moisture buildup, which can exacerbate rusting. A protective coating can also be applied to enhance their resistance against the elements.

Lubrication is another critical aspect of maintaining iron cable drums. Ensure that the moving parts are properly lubricated to prevent friction and wear. Use suitable lubricants that are compatible with iron to avoid chemical reactions that could lead to deterioration. Additionally, avoid overloading the drums and ensure that cables are properly wound and secured to prevent tangling and damage. By following these best practices, you can extend the life of your iron cable drums and ensure they function efficiently in your applications.

Iron Cable Drum Usage and Maintenance Insights

This bar chart illustrates the impact of various factors on the performance of iron cable drums. Regular maintenance yields the highest positive effect, while factors like improper handling and load capacity significantly affect drum performance.