The Ultimate Guide to Choosing the Right Iron Cable Drum in 2026

Choosing the right iron cable drum can be daunting. In 2026, the industry is evolving rapidly. New designs and materials are emerging.

Iron cable drums play a crucial role in various sectors. They ensure the safe and efficient storage of cables. Yet, many buyers overlook important factors when selecting one. Understanding load capacity, durability, and size can make a difference. A misstep in this choice can lead to operational challenges.

Consider the intended use and environment. For outdoor conditions, weather-resistant features matter. Oversized or undersized drums may not function effectively. Reflecting on these details, buyers can avoid common pitfalls. Selecting an iron cable drum isn’t just about price; it’s about making an informed decision.

Understanding the Basics of Iron Cable Drums and Their Applications

Iron cable drums are essential tools in various industries. They are designed to handle heavy cables, making them crucial for electrical and telecommunications projects. The material, iron, offers strength and durability, which is important for long-term use. Understanding their structure helps in selecting the right type for your needs.

These drums come in various sizes and shapes. Larger drums are often used for construction sites, while smaller ones find use in workshops. The capacity of the drum matters a lot. If you choose wrongly, it may lead to safety hazards. Think about the weight of the cable. Will the drum support it properly?

Inspecting the drum's finish is also vital. A rough finish might catch on the cables, leading to wear and tear. Likewise, the weight distribution can impact how easily the drum can be moved. Be mindful of these details; a small oversight can lead to significant problems down the line.

Key Factors to Consider When Choosing an Iron Cable Drum

Choosing the right iron cable drum involves several important factors. Size is crucial. It should fit your project needs perfectly. Too small, and you risk overloading it. Too big, and it becomes cumbersome. Weight capacities vary, so check specifications diligently. You need to balance durability and manageability, especially on-site.

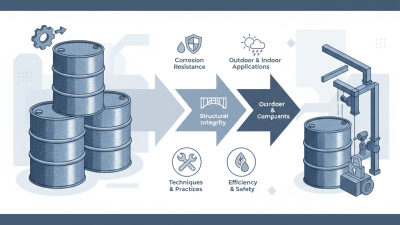

Material quality is another key aspect. High-strength steel is preferred for reliability. However, keep an eye on corrosion resistance. Environmental conditions can affect longevity. A drum exposed to moisture may deteriorate quickly. Consider investing in protective coatings, yet remember that they might add extra costs.

Lastly, consider the design. Ergonomic features can enhance usability on the go. Easy-to-grip handles may prevent accidents. But, some designs sacrifice stability for convenience. Reflect on your priorities. A good drum should cater to your operational needs while remaining flexible for different tasks. Always weigh the pros and cons before making a decision.

The Ultimate Guide to Choosing the Right Iron Cable Drum in 2026 - Key Factors to Consider When Choosing an Iron Cable Drum

| Dimension |

Material |

Capacity (kg) |

Weight (kg) |

Recommended Use |

| 800x600x400 mm |

Steel |

1000 |

80 |

Heavy-duty cable storage |

| 1000x800x600 mm |

Galvanized Steel |

1500 |

120 |

Industrial wiring |

| 750x550x450 mm |

Carbon Steel |

800 |

60 |

Construction sites |

| 1500x1200x800 mm |

Stainless Steel |

3000 |

200 |

Long-term storage |

| 500x400x300 mm |

Mild Steel |

300 |

30 |

Light-duty cable handling |

Types of Iron Cable Drums: A Comparative Overview

When selecting an iron cable drum, understanding the types available is crucial. There are multiple styles, each designed for specific applications. For instance, the open reel drum is simple yet effective for general tasks. It allows easy access to the cable while in use. However, it may not provide maximum protection.

In contrast, closed or enclosed drums offer better safety. They protect the cable from environmental factors. Yet, these can be bulkier and may require more storage space. Deciding between convenience and protection can be challenging.

Additionally, consider the size and capacity of the drum. A larger drum can hold more cable, reducing the need for frequent changes. But it can also be heavy and cumbersome. Sometimes, simplicity trumps size. We might overthink our choices, focusing too much on features rather than practical needs. Clarity in purpose is essential. Choose what best fits your situation.

Maintenance Tips for Prolonging the Life of Iron Cable Drums

Iron cable drums are essential for many operations. Maintaining them can significantly extend their lifespan.

Regular inspections are crucial. Look for signs of wear, such as rust or cracks. Taking a few minutes to check these can prevent larger issues later.

Cleaning your iron cable drums helps too. Dust and debris can accumulate, causing problems. Use a dry cloth to wipe them down periodically.

Lubrication is key for moving parts. A little grease can make a big difference.

Don’t overlook this step.

Storing the drums properly is equally important. Keep them in a dry place, away from moisture.

Moisture leads to corrosion, which is hard to reverse. Lastly, consider the load capacity. Overloading can cause damage.

Be mindful of weight limits to avoid future headaches. Maintenance matters; a few adjustments today can save you time and money tomorrow.

Future Trends in Iron Cable Drum Technology for 2026 and Beyond

As we look toward 2026, the iron cable drum industry is set to experience significant technological advancements. A recent report by the Global Wire & Cable Drum Market estimates that the sector will grow by 7.5% annually. Innovations in materials and design can enhance strength and reduce weight. These improvements are crucial as construction and utility sectors demand more efficient solutions.

Smart technology integration is another trend gaining traction. Sensors can monitor cable wear and drum integrity. This could lead to predictive maintenance, minimizing downtime. A study highlighted that up to 30% of breakdowns arise from equipment neglect. However, adopting such technologies poses challenges. Many businesses may struggle with the costs and training required.

Sustainability is also a vital consideration. The push for eco-friendly materials is influencing production methods. Companies need to balance performance and environmental impact. Indeed, 64% of industry leaders agree that embracing sustainable practices is essential. The journey towards sustainable iron cable drums is complex but necessary.