How to Choose and Maintain a Galvanized Iron Drum for Optimal Use

When it comes to storage and transportation needs, the galvanized iron drum stands out as a robust and reliable solution. Its corrosion-resistant properties, combined with structural strength, make it an ideal choice for various applications, from industrial usage to personal projects. However, selecting the right galvanized iron drum and maintaining it properly are crucial steps to ensure optimal functionality and longevity.

Understanding the different specifications and features of galvanized iron drums can significantly impact their performance. Whether you are looking for a drum for chemical storage, waste disposal, or other purposes, it is essential to consider factors such as size, thickness, and the compatibility of materials. Additionally, proper maintenance measures must be employed to prolong the life of your galvanized iron drum, ensuring it remains safe and effective throughout its use.

In this guide, we will explore the key aspects of choosing and maintaining a galvanized iron drum, providing you with practical tips and insights that will help you make informed decisions. By following these guidelines, you can maximize the benefits of your galvanized iron drum and ensure it meets your requirements effectively.

Understanding Galvanized Iron Drum Specifications and Standards

When choosing a galvanized iron drum, understanding its specifications and standards is crucial for ensuring quality and performance. Galvanized iron drums are typically constructed with a coating of zinc, which provides protection against corrosion. This makes them ideal for storing various materials, including liquids and solids, in diverse environments. Familiarize yourself with thickness measurements, such as gauge levels, as this affects the drum's durability and load capacity.

Tips: Always check for compliance with industry standards such as those set by the American National Standards Institute (ANSI) or the American Society for Testing and Materials (ASTM). These standards ensure that the galvanized iron drums meet safety and performance criteria that are essential for their intended use.

Moreover, consider the capacity of the drum relative to its intended application. Common capacities range from 5 to 55 gallons, and selecting the right size is vital to avoid overfilling or wastage. Additionally, assess the barrel's weld integrity and protective finish to guarantee longevity and reliability in various conditions.

Tips: Regularly inspect the drum for any signs of wear, including rust on the exterior or interior lining. Maintaining the integrity of the drum not only prolongs its usefulness but also enhances safety during storage and transport.

Key Factors in Selecting the Right Size and Capacity for Your Needs

When selecting a galvanized iron drum, one of the most critical considerations is the size and capacity suitable for your specific needs. According to industry reports, a significant percentage of users—over 40%—fail to choose proper drum sizes, leading to inefficiencies and increased costs. The primary factors to consider include the volume of materials to be stored, the space available, and the weight capacity required. Typically, galvanized drums come in sizes ranging from 15 gallons to 55 gallons. A clear assessment of your storage requirements will help ensure that you invest in the right barrel.

Tips: Always measure the intended storage space and account for any necessary accessibility requirements. This will help avoid the common mistake of purchasing a drum that is either too large or too small for your environment.

Another important aspect is understanding the type of materials that will be stored within the drum. For example, if you are planning to store liquids, opting for a drum with a larger capacity may be advantageous, as this reduces the frequency of refills. Additionally, consider the weight of the material; overweight drums can lead to potential handling hazards. Data from safety organizations indicate that improperly loaded drums are a leading cause of workplace accidents.

Tips: To ensure safety and compliance, always adhere to the manufacturer’s specifications concerning maximum load capacities and consider periodic checks for wear and tear, ensuring your galvanized iron drum remains optimal for your storage needs.

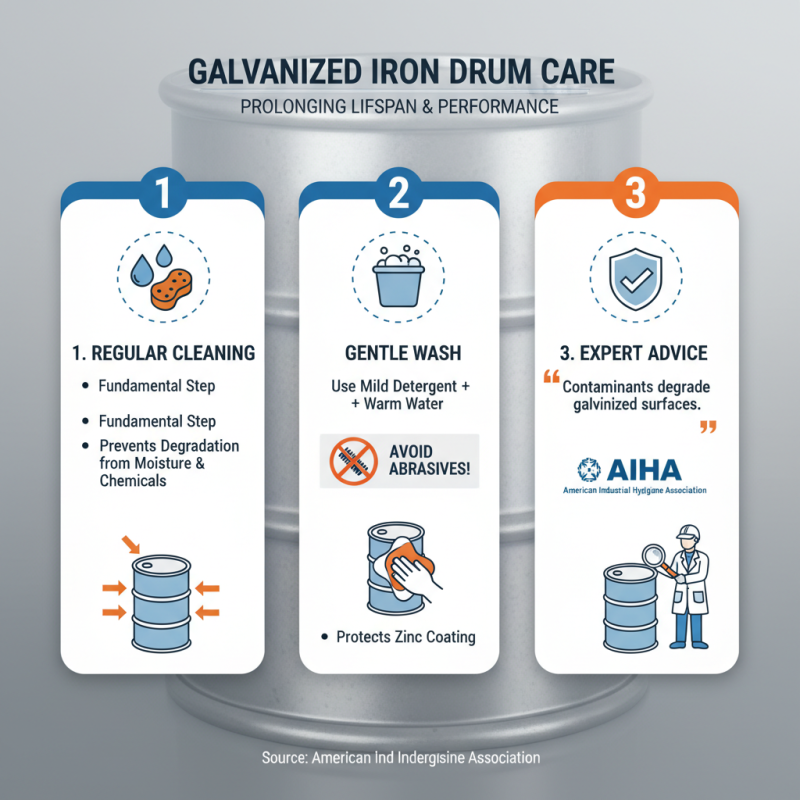

Best Practices for Cleaning and Maintaining Galvanized Iron Drums

When it comes to maintaining galvanized iron drums, adhering to best practices is essential for prolonging their life and ensuring optimal performance. Regular cleaning is a fundamental step in drum maintenance. According to the American Industrial Hygiene Association, contaminants like moisture and chemicals can significantly degrade galvanized surfaces if left unaddressed. Therefore, it's crucial to clean the drum regularly using a gentle detergent mixed with warm water. Abrasive materials should be avoided to prevent scratching the protective zinc coating.

Tip: Rinse the drum thoroughly after cleaning to remove any detergent residue, as leftover chemicals can corrode the metal over time.

In addition to regular cleaning, inspections play a key role in maintenance. It is recommended that users check the drums periodically for signs of rust or damage. The National Association of Corrosion Engineers suggests that corrosion can begin on exposed areas within just a few months if a drum is not well maintained. Proper storage in a dry, well-ventilated area can further prevent rust build-up.

Tip: Keeping a maintenance log can be beneficial. Documenting cleaning schedules and inspections ensures that user practices stay consistent and effective over time.

By following these best practices, users can significantly enhance the lifespan and usability of their galvanized iron drums.

Common Issues and Solutions for Galvanized Iron Drum Longevity

Maintaining a galvanized iron drum is crucial for extending its lifespan and ensuring optimal performance. Common issues include corrosion, structural integrity, and improper sealing. According to a report from the National Association of Corrosion Engineers, corrosion can reduce the effective life of steel drums by 30-50% if not properly addressed. Regular inspection for rust spots and signs of wear can help identify potential issues early, allowing for timely maintenance such as repainting or applying protective coatings.

Another significant concern is the integrity of the drum under varying temperature conditions. Studies indicate that changes in temperature can lead to expansion and contraction of the material, putting stress on seams and joints. To combat this, users should store galvanized drums in temperature-controlled environments when possible and avoid exposing them to extreme conditions. Furthermore, ensuring that the drum is properly sealed can prevent contamination and maintain the quality of its contents. Implementing these preventive measures will not only enhance the longevity of galvanized iron drums but also optimize their overall functionality in industrial applications.

Environmental Considerations for the Proper Disposal of Used Drums

When it comes to the proper disposal of used galvanized iron drums, environmental considerations are paramount. These drums, often utilized for storing various substances, can pose significant risks if not disposed of correctly. First and foremost, it is essential to ensure that all residual materials are emptied and disposed of in a manner that adheres to local regulations. Residual chemicals or substances can leach into the soil and water sources, causing contamination and harm to ecosystems.

Recycling is a viable option for ensuring sustainable disposal of galvanized iron drums. Many recycling centers accept metal containers, allowing for the steel to be repurposed into new products rather than ending up in a landfill. Before dropping the drum off for recycling, it is crucial to check with the facility to confirm they accept such materials, as well as to learn about any necessary preparation steps to ensure safe handling. Moreover, some communities have designated hazardous waste collection days for the disposal of drums that previously held hazardous materials, which helps mitigate environmental risks associated with improper disposal. Proper disposal practices not only protect our environment but also promote recycling efforts, ultimately contributing to a cleaner planet.

How to Choose and Maintain a Galvanized Iron Drum for Optimal Use - Environmental Considerations for the Proper Disposal of Used Drums

| Aspect |

Description |

| Material Quality |

Choose drums made from high-quality galvanized steel to prevent rust and corrosion. |

| Capacity |

Select an appropriate size (e.g., 55-gallon) based on your storage and transport needs. |

| Maintenance |

Regularly inspect for leaks or damage; clean and repaint if necessary. |

| Storage Conditions |

Store in a cool, dry place away from direct sunlight to extend the drum's lifespan. |

| Disposal Methods |

Follow local regulations for disposing of used drums; consider recycling options. |

| Environmental Impact |

Ensure proper disposal to minimize environmental pollution and health risks. |