Best Iron Cable Drum Options for Heavy Duty Cable Management

In the realm of heavy-duty cable management, the choice of equipment plays a pivotal role in ensuring efficiency and safety. One of the standout solutions is the iron cable drum, which offers unparalleled durability and support for extensive cable systems. According to a report by MarketsandMarkets, the global cable management market is projected to grow significantly, reaching a valuation of $20 billion by 2026, driven by the increasing demand for robust industrial infrastructure and an ever-expanding telecommunications network. This growth underscores the necessity for reliable equipment like iron cable drums, specifically designed to handle the weight and complexity of high-capacity cables.

Iron cable drums are engineered to withstand harsh environments and heavy loads, making them ideal for construction sites, manufacturing plants, and large-scale events. A study by Research and Markets indicates that the industrial cable management solutions segment is expected to witness a CAGR of 8.3% from 2021 to 2026, highlighting a growing recognition of the importance of using high-quality materials. With their superior strength and longevity, iron cable drums not only enhance operational efficiency but also contribute to safety standards in workplaces where cable clutter can lead to accidents. Selecting the best options in iron cable drums is, therefore, a critical consideration for businesses looking to optimize their cable management strategies.

Overview of Iron Cable Drums for Heavy Duty Use

Iron cable drums play a crucial role in heavy-duty cable management, supporting the safe and efficient storage of cables used in various industrial applications. These durable drums, made from high-quality iron materials, are designed to withstand extreme conditions and heavy loads.

According to a recent industry report by Market Research Future, the global market for industrial cable management solutions, including iron cable drums, is projected to grow at a CAGR of 6.5% by 2026, highlighting the increasing importance of robust cable management systems in modern industries.

When selecting the right iron cable drum, consider factors such as weight capacity, corrosion resistance, and compatibility with your specific cable sizes. It’s essential to choose drums that not only meet your operational needs but also comply with safety standards. For heavy-duty applications, look for drums that feature reinforced designs to prevent deformation under substantial weight.

Tips: Ensure proper maintenance of your iron cable drums by regularly checking for rust or structural damage. Additionally, consider labeling each drum clearly to facilitate easy identification and access to cables. Implementing these strategies can significantly extend the lifespan of your cable management solutions.

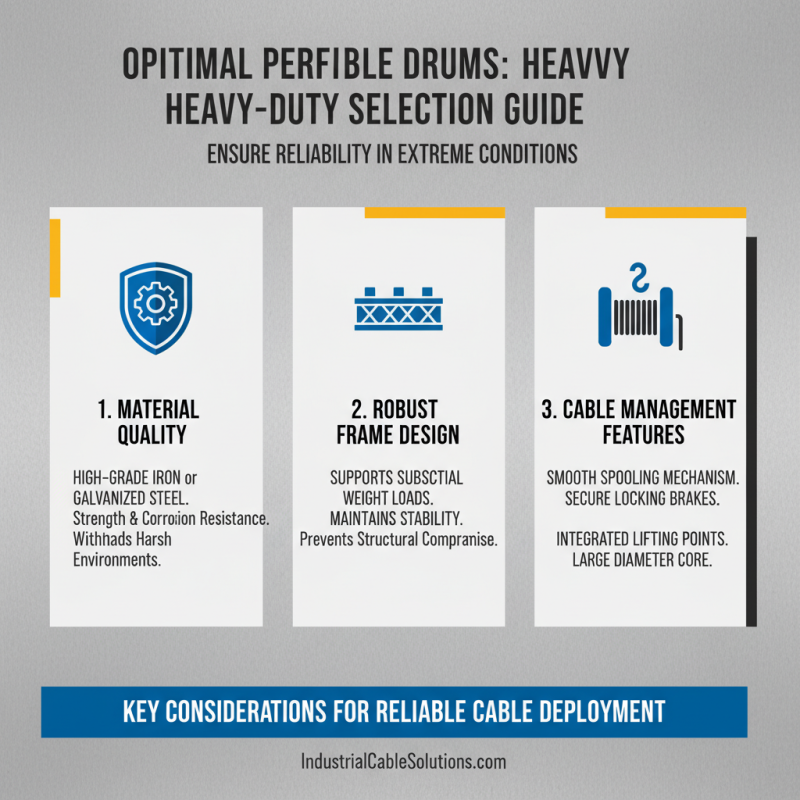

Key Features to Consider in Heavy Duty Cable Management

When selecting iron cable drums for heavy-duty cable management, there are several key features to consider ensuring optimal performance and durability. First and foremost, the material quality is crucial; high-grade iron or galvanized steel is recommended for its strength and resistance to corrosion. This ensures that the drum can withstand prolonged exposure to harsh environments without compromising its structural integrity. Additionally, look for drums with a robust frame design that can support substantial weight loads while maintaining stability during operation.

Another essential feature is the drum's capacity and size. It is vital to choose a cable drum that can accommodate the specific length and thickness of the cables you plan to manage. Proper sizing not only facilitates easier handling and deployment of cables but also helps prevent tangling or damage during storage. Furthermore, consider the portability of the drum; models with integrated handles or wheels enhance maneuverability, making it easier to transport on job sites. Lastly, inspection capabilities such as slots or clear panels allow users to monitor cable condition without unrolling, enhancing efficiency in maintenance and ensuring your cables remain in top shape.

Comparison of Different Iron Cable Drum Materials

When it comes to heavy-duty cable management, the material of the iron cable drum plays a crucial role in determining its durability and efficiency. The most common materials used for manufacturing these drums include galvanized steel, wrought iron, and cast iron. Galvanized steel is favored for its corrosion resistance, making it an excellent choice for outdoor applications or environments prone to moisture. Its lightweight nature allows for easy handling while still providing adequate strength to support heavy cables.

On the other hand, wrought iron drums are known for their malleability and strength, allowing them to withstand significant loads without deforming. They provide a perfect balance between durability and flexibility, making them suitable for various industrial settings. Conversely, cast iron offers impressive weight-bearing capabilities and is often selected for stationary applications where stability is paramount. While cast iron drums may be heavier, their ability to absorb vibrations helps protect sensitive cables during transportation and storage. Each material presents unique advantages, making it essential to choose based on specific operational requirements and environmental conditions.

Comparison of Iron Cable Drum Materials for Heavy Duty Cable Management

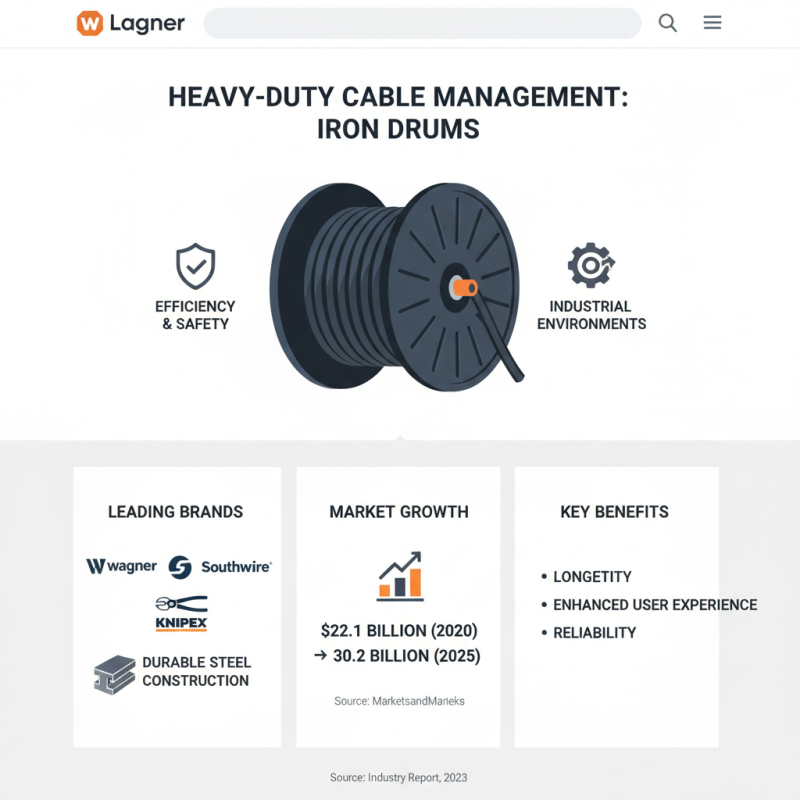

Best Brands and Models for Heavy Duty Cable Drums

When it comes to heavy-duty cable management, selecting the right iron cable drum is crucial for efficiency and safety in industrial environments. Leading brands such as Wagner, Southwire, and KNIPEX have established themselves as top contenders, offering innovative designs that enhance user experience. For instance, Wagner's heavy-duty models incorporate durable steel construction, ensuring longevity even in the most demanding applications. According to a recent industry report by MarketsandMarkets, the global cable management system market is expected to grow from $22.1 billion in 2020 to $30.2 billion by 2025, highlighting the increasing demand for reliable cable management solutions.

In addition to brand reputation, the specific models available on the market cater to various heavy-duty applications. Southwire's portable cable drum features a 1000-foot capacity, allowing for efficient bulk cable handling while minimizing the risk of tangling or damage. The KNIPEX series boasts valuable ergonomics designed for ease of handling under strenuous conditions, which is paramount given that workplace accidents related to improper cable handling can lead to significant downtime and increased operational costs. With data from the Occupational Safety and Health Administration (OSHA) indicating that electrical hazards caused about 1,000 injuries annually, investing in quality cable drums becomes not just a choice but a necessity for maintaining workplace safety and efficiency.

Maintenance Tips for Longevity of Iron Cable Drums

When it comes to maintaining the longevity of iron cable drums, regular inspections and proper care are essential. Begin by routinely checking for any signs of wear and tear, such as rust or deformation, as these can affect the drum's performance. Keeping the surface clean and free of debris will not only enhance its appearance but also prevent corrosion. Using protective coatings designed for metal can further mitigate the risk of rust, extending the life of the drum significantly.

Additionally, it's vital to ensure that cable drums are appropriately stored when not in use. Avoid exposing them to harsh weather conditions that can cause deterioration. If possible, store them in a climate-controlled environment. Furthermore, when loading cables onto the drums, distribute the weight evenly to prevent unnecessary strain on the structure. By following these maintenance tips, you can ensure that your iron cable drums will serve you well for years to come.

Best Iron Cable Drum Options for Heavy Duty Cable Management - Maintenance Tips for Longevity of Iron Cable Drums

| Drum Size (mm) |

Weight Capacity (kg) |

Material |

Recommended Use |

Maintenance Frequency |

| 600 |

2000 |

Steel |

Construction Sites |

Every 3 months |

| 800 |

3500 |

Galvanized Steel |

Industrial Wiring |

Every 6 months |

| 1000 |

5000 |

Iron |

Manufacturing Plants |

Yearly |

| 1200 |

7000 |

Reinforced Steel |

Telecommunication |

Every 2 months |

| 1500 |

10000 |

Heavy-duty Steel |

Power Distribution |

Every 4 months |