2026 Top Used Iron Drum for Sale Options for Your Business Needs?

In today's industrial landscape, businesses need efficient storage solutions. One option that stands out is the used iron drum for sale. These drums offer durability and versatility for various applications. Companies looking to optimize costs often turn to the second-hand market.

Used iron drums are not just affordable; they are practical. Many have features that suit diverse business needs. However, the quality can vary widely. Buyers should carefully assess the condition before purchase. Some drums may show signs of wear, making it essential to be vigilant.

While used iron drums can serve many purposes, it is crucial to reflect on your specific requirements. The right drum can enhance operational efficiency. Yet, opting for the first available option might lead to challenges down the road. Businesses should ensure that they select with caution, maximizing value and functionality.

2026 Market Trends for Used Iron Drums: Demand and Supply Analysis

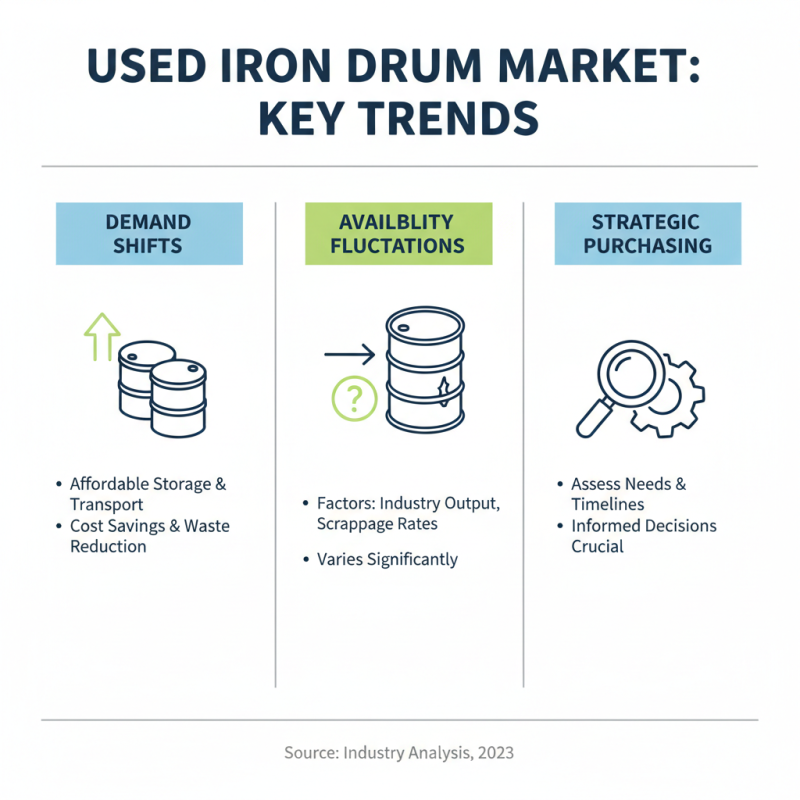

The market for used iron drums has shown notable shifts in demand. Many businesses seek affordable solutions for storage and transportation. Companies often opt for used options to save costs and reduce waste. However, the availability can fluctuate significantly based on various factors. It's crucial for businesses to assess their specific needs and timelines to make informed purchases.

Supply issues frequently arise, leading to a competitive market environment. Some suppliers struggle to meet demand, while others may offer low-quality products. Buyers need to be vigilant. Inspecting drums for rust, dents, or contamination is vital. This can prevent future problems and ensure safety.

Market trends indicate a growing interest in eco-friendly practices. Many companies aim to reduce environmental impact by reusing materials. This shift can enhance brand image and attract consumers. Yet, businesses must tread carefully. The balancing act of cost, quality, and sustainability can be tricky. Identifying reliable suppliers is key to success in this evolving market.

Key Factors Influencing the Prices of Used Iron Drums in 2026

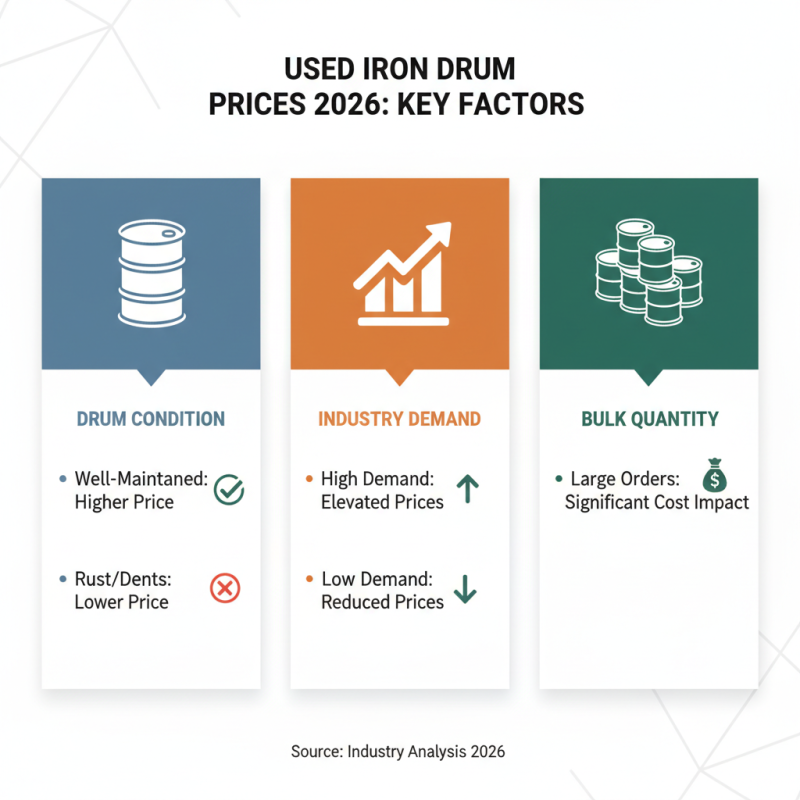

When considering used iron drums for sale in 2026, various factors influence their prices. The condition of the drum is paramount. A well-maintained drum commands a higher price. Rust and dents, however, can deter buyers. The demand in specific industries also plays a role. Higher demand often results in elevated prices. For businesses needing large quantities, this can become significant.

Another factor is location. Prices may vary greatly between regions. In urban areas, for instance, the supply might be lower. This drives prices up. Shipping costs can add to the final price as well. It’s essential to include these in your budget.

Finally, the market trends should be monitored. Fluctuations in raw material costs impact used iron drum prices. The global economy affects availability. While these factors provide guidance, discrepancies exist. Not every price aligns with expectations. Understanding these nuances is crucial for making informed purchasing decisions.

Top Applications of Used Iron Drums Across Different Industries

Used iron drums are versatile containers with a range of applications across industries. Many manufacturers utilize them for storage and transportation. They are commonly used in the chemical and petroleum sectors for safe shipping. These drums hold liquid, oils, and even solid materials efficiently.

In agriculture, used iron drums serve as reservoirs for water and fertilizers. Farmers appreciate their durability and resistance to rust. Some also use them for creative tasks, like rainwater harvesting. However, the condition of the used drum matters. A rusty, damaged drum can become a liability.

The food industry sometimes adopts these drums for bulk storage. But this practice raises concerns about contamination. Ensuring cleanliness is crucial but often overlooked. Not every business performs adequate checks before reuse. Ignoring these standards could lead to significant risks. The careful choice of used iron drums directly impacts operational efficiency. Each industry must reflect on their use of these containers.

2026 Top Used Iron Drum for Sale Options for Your Business Needs? - Top Applications of Used Iron Drums Across Different Industries

| Industry |

Application |

Typical Size (L) |

Material Type |

Estimated Cost ($) |

Availability (Units) |

| Chemical Manufacturing |

Storage of Chemicals |

200 |

Steel |

150 |

500 |

| Food Processing |

Transport of Ingredients |

100 |

Stainless Steel |

200 |

300 |

| Pharmaceutical |

Bulk Storage |

50 |

Coated Steel |

250 |

200 |

| Construction |

Kerosene Storage |

150 |

Iron |

120 |

400 |

| Automotive |

Lubricant Storage |

300 |

Galvanized Steel |

180 |

250 |

Major Suppliers and Distributors of Used Iron Drums in 2026

When looking for used iron drums for business needs, major suppliers play a crucial role. Many businesses explore options from local and regional distributors. They often have varied sizes and conditions of drums. This diversity can be beneficial for cost-effective solutions. Some suppliers specialize in refurbishing used drums, ensuring safety and compliance. Others focus on bulk sales, which can lower individual costs.

However, not all suppliers are equal. It’s important to assess quality. Some suppliers may have inconsistent stock levels or unclear sourcing practices. Businesses might face challenges in verifying the condition of the drums. Engaging with multiple distributors can help gauge the market. It’s useful to ask about their return policies and warranties. This information can make a significant difference.

Each supplier has unique offerings. While some may promise fast delivery, others may lack responsive customer service. These inconsistencies can lead to delays or miscommunications. Businesses should actively seek feedback from peers to navigate these challenges effectively. Building relationships with reliable distributors can also enhance long-term partnerships. This approach can lead to better procurement strategies over time.

Environmental Impact and Recycling Opportunities for Iron Drums

Iron drums are widely used in various industries. Their durability makes them ideal for storage. However, the environmental impact is significant. According to a 2022 report, around 2.6 million tons of iron drums end up in landfills each year. This number highlights the need for better recycling practices.

Recycling iron drums can reduce waste and conserve resources. The recycling process recovers about 95% of the iron. This statistic shows the effectiveness of recycling programs. Yet, many businesses overlook recycling options. A survey indicated only 30% of companies actively recycle their used drums. This negligence contributes to environmental degradation.

Moreover, improper disposal impacts ecosystems. Chemicals from leftover materials can leach into soil and water. Communities are left to deal with contamination issues. Companies must reflect on their waste management strategies. By seeking recycling opportunities, they can improve their sustainability footprint. Investing in responsible practices can lead to a healthier environment for all.

2026 Top Used Iron Drum for Sale Options for Your Business Needs

This chart illustrates key attributes related to the 2026 used iron drum market. The data highlights recyclability, costs, supply availability, and environmental impact to aid businesses in making informed decisions for their operational needs.